|

Taitonga - Centerboard repair - Verklemmtes Kielschwert lösen und Leinen reparieren

|

|

1) How to replace the line for getting the centerboard up on an Ovni 395 2) How to hammer down a stucked centerboard 1) Kielschwert Aufholerleine austauschen 2) Verklemmtes Kielschwert runterhämmern |

|

Shelter Bay Marina stored us about a meter high, so we requested to lift us before we launch to get an opportunity to get some antifouling on the centerboard. They lifted us for 1,5h and we did a quick job. Then we had to get the centerboard in again for restorage. Before launchinf we tired the centerboard to mark the meters. Up was ok, down was not possible. It was stuck. We hoped that it we go down in the water and need another angle. During lauch nothing happend. We were put in the same place again and charged for 1/2 haulout! |

|

1) Replacing the line for getting the board-up ca. 3h, 1Person, not easy, metric tools and heavy, special tools  Getting the centerboard down with the suppose line did not work. The schekel (how is that spelled?) broke |

We removed the boards above the centerboard between the tables |

We opened all 3 hatches to have a look at the problem. here aft |

here center |

here center looking aft |

center with the lines crossing. The marks for the waterline seem to be over the level of the inspectionhatch! |

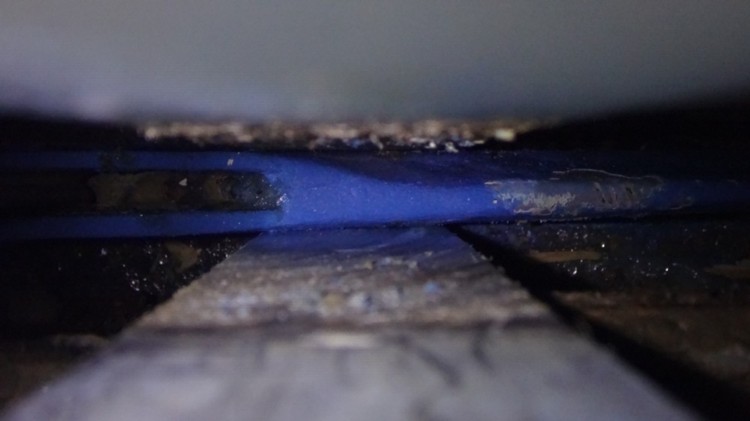

aft: our supposed problem => No space between board and wall due to paint, dirt and barnacles |

front: The attaching point for the line to take the board down |

front: The marks for the waterline are clearly to see under the inspectionhatch |

Looks a bit odd. The inspection hatch and the openings under the table are not matching (but it is doable) |

We had to replace the line for getting the centerboard UP (note the watermarks on the plate). I worked on the portside, because it seemed easier to get to the screws inside. To get this plate out I took the screws away and found out the plate is glued to the structure. I hammered it out with a 2-kilo-hammer, my biggest screwdrivers AND the stainless-steal-bar for securing our entrance (longer than my arm, ca. 5mm thick). Without the stainless-steal-bar it would not have happend. |

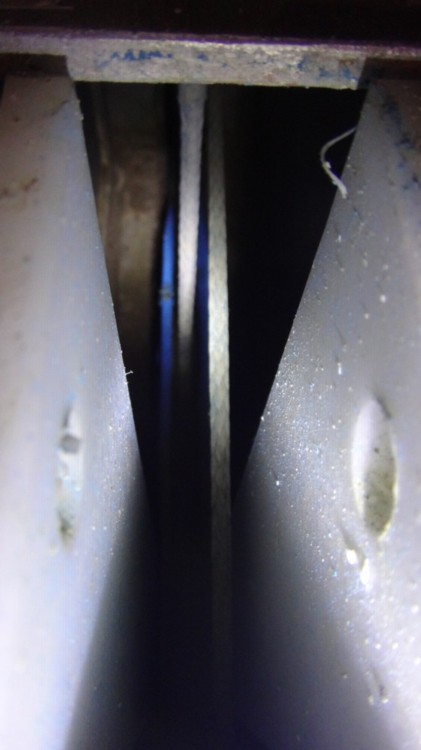

a look inside |

the rolls, front for getting it down |

the roll in the centerboard |

the roll in the centerboard (same) |

Attachingpoint for the line to get the centerboard up allenkeybolt port / screw starboard |

I made a tackling and did not remove the mantle (hope that this is ok!) |

|

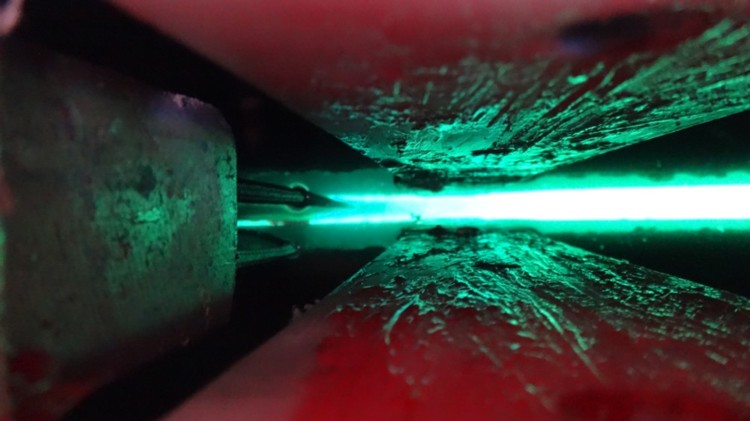

2) Hammering the centerboard down ca. 2h, 1Person, not easy, heavy, special tools  I used the aft top inspectionhatch. I tried my 2-kilo-hammer with a wood first => it splintered (Maybe the handle of an axe (if it fits) would be stronger) I then took a piece of a metalltube to hammer it down. It worked! |

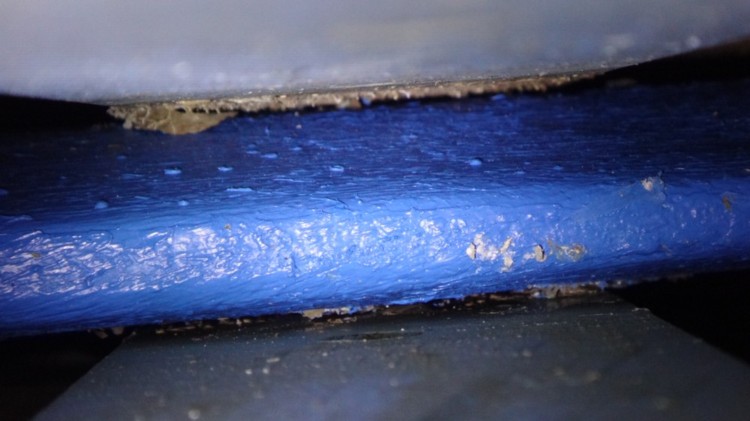

Cleaning the surface of the Delrinplates |

Preparing to grease the plates 1 |

Preparing to grease the plates 2 |

Marks ot the antifouling going apart and signs of the grease |

I reduced the antifouling layer with sanding |

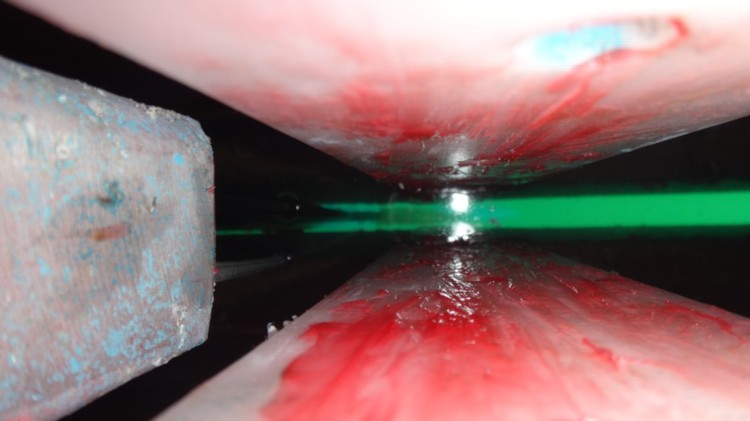

After launching a look in the inspectionhatch where I hammered it down |

I closed the hatch and sealed it. The metalltube found a place in the locker. |

|

I found some older Infos on an other boatsize:

SY Kaya, Ovni 30, 1992, Ruder und Schwertreparatur |

|

Taitonga.net, © Dagmar und Christian Sahr, |